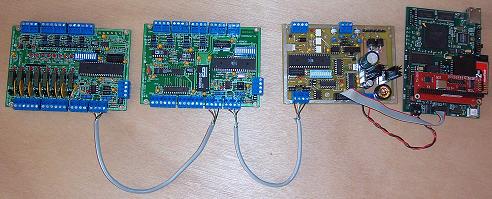

ICON

I/O Overview

Introduction

The ICON controller connects to a Power/Bus

module for power and to convert the controller's RS232 interface to

Modbus RS485 interfaces for interfacing Modbus I/O devices. The

Power/Bus module also has a Dallas 1-wire bus interface for

interfacing Dallas 1-wire I/O devices and sensors.

The ICON Modcombo I/O module provides 10

inputs and 8 outputs for interfacing sensors and controlling

devices. Other Modbus devices from other manufacturers that support

the Modbus RTU serial or TCP protocol are supported.

Modcombo Power/Bus Controller

Power/Bus Module

The Power/Bus module accepts an unregulated

input of nine to 24 VDC or VAC and generates regulated +5V for

powering the ICON controller and other Modbus I/O devices. This

module also has two RS485 Modbus interfaces, one isolated and one

non-isolated and one Dallas Semiconductor 1-wire device interface

bus.

There are two configurations for

the Power/Bus module. The first configuration is used in conjunction

with the ICON controller and converts the ICON controller's RS232 interface into two Modbus interfaces, a local non-isolated

RS485 bus for Modbus I/O devices

located next to the controller and

an isolated RS485 Modbus to interface

Modbus devices located up to 4000 feet from the

controller.

The second configuration is designed for

remote locations. In this configuration the Power/Bus module connects to the isolated RS485 Modbus

and converts to a local RS485

Modbus for one or more Modbus

I/O devices located with the remote

Power/Bus module. It also supplies power to these I/O

devices.

The system supports one local Power/Bus module with controller

that can communicate with up to 31 remote Power/Bus modules. Total

cable length is 4000 feet. Up to 254 Modbus I/O devices

can theoretically be connected to this Modbus network. In

reality throughput considerations limit the number to something much less.

Each Power/Bus module also contains

a Dallas Semiconductor 1-wire device bus. This bus can support up to 127, 1-wire devices such

as temperature probes with total bus lengths up to 1000 feet

long. The 1-wire devices are controlled from Modbus registers written to

and read from the Power/Bus module. Therefore, from a

programmer's perspective, the Dallas 1-wire devices look like Modbus devices.

Modcombo I/O module

The Modcombo modules connect to the

non-isolated Modbus from a Power/Bus module. This bus supplies +5V

power to the unit along with the the RS485 Modbus signals. Each

Modcombo board has the following specifications:

-

All 10 inputs can be selected for

digital input

-

The first 8 inputs can be selected for

analog input on a channel by channel basis

-

All 10 input channels can do event

counting, slow speed on channels 1-8 (5HZ max) and high speed

(10KHZ) on channels 9 and 10

-

Inputs 9 and 10 can also measure

frequency

-

All 8 outputs are single pole relays

than can switch up to 30VDC or 110VAC non-inductive loads up to

three amps

Interface

Specifications for all Modbus devices

- Serial RTU Modbus (TCP Modbus is also

supported but its operation is over the ethernet port) Baud rate of 9600 or 19200 switch

selectable

- Parity can be selected for none or odd.

- Unit address of 1 to 255 switch

selectable

- Supports Modbus commands 1, 2, 3, 4, 5,

6, 15 and 16

Last updated

December

5,2012

|

![]()